SAMZOON Automotive Production Workshop Laboratory Soundproof Panel

Product parameters:

Effective width: 1150 mm/non-standard ≦ 1180 mm

Thickness of the product: 50mm/75mm/100mm/125mm/175mm/200mm (MAX 300mm)

length: according to user needs and the project request size production (generally) ≦ 8000 mm

Installation structure: male and female mouth splicing

Product description:

1.Soundproof board in the laboratory of the automobile production workshop

Utilizing precision CNC punching technology, a dual-row array of 25mm apertures is uniformly formed on the surface of the color-coated steel plate. Combined with a 0.4-0.6mm thick galvanized substrate, the strip-shaped perforations deliver exceptional noise reduction of 20-40 dB (meeting China's noise standards: daytime ≤50 dB, nighttime ≤40 dB). This configuration creates an optimized Helmholtz resonance structure. Tested by national acoustic laboratories, the Noise Reduction Coefficient (NRC) reaches 0.85 within the 500-4000Hz frequency range, effectively eliminating standing waves and reverberation.

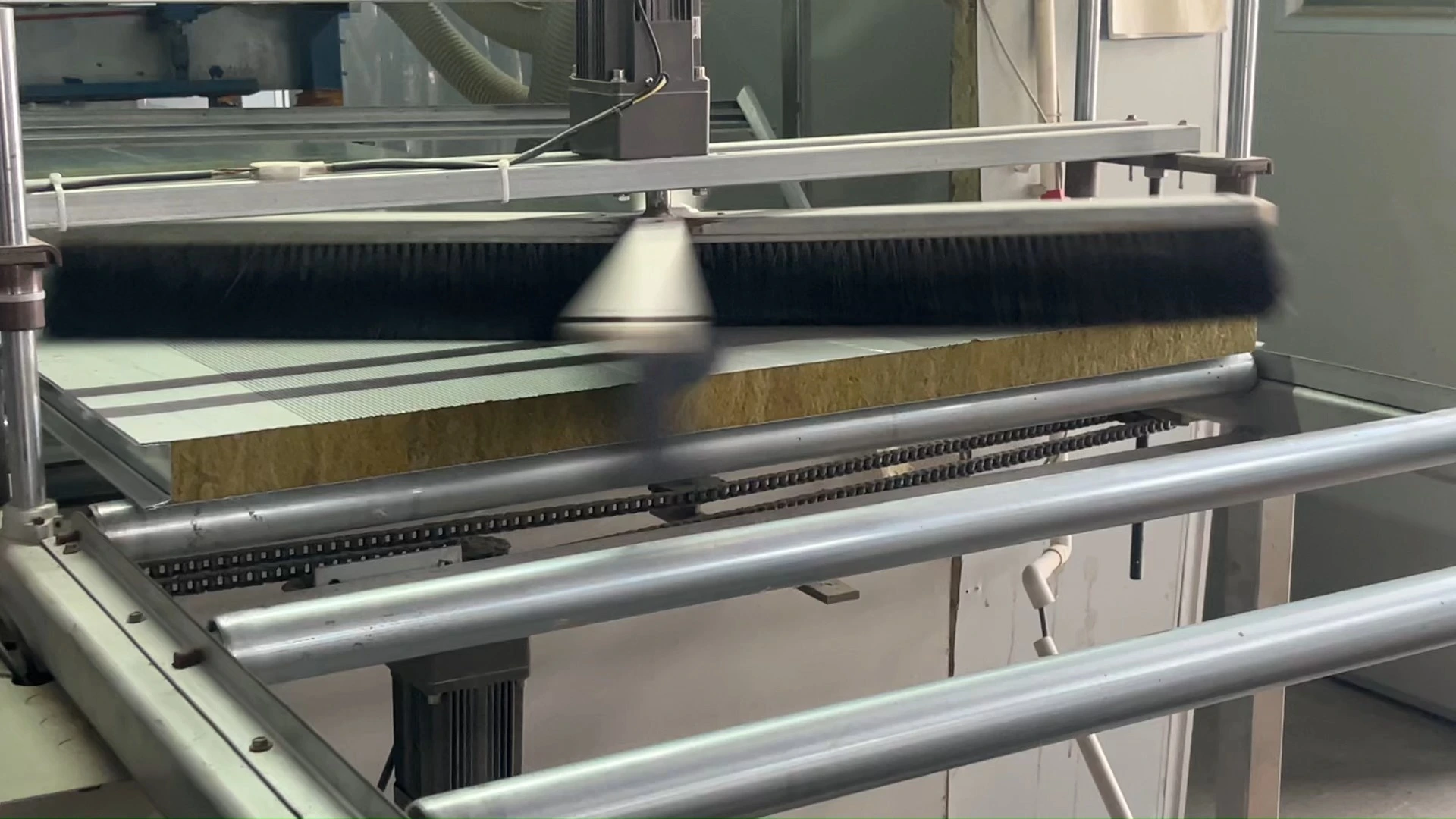

- Composite Lamination Process

A proprietary cold-bending lamination technique seamlessly integrates 100kg/m³ high-density basalt rock wool core material with 0.4-0.6mm color-coated steel plates. This innovation achieves a bending strength of 320MPa, overcoming the deformation issues common in traditional acoustic panels. The product meets Class A fire safety certification, ensures durability across all climates, and adheres to eco-friendly standards with zero pollution emissions.

SOUNDPROOF BOARD IN THE LABORATORY

OF THE AUTOMOBILE PRODUCTION WORKSHOP

A proprietary cold-bending lamination technique seamlessly integrates 100kg/m³ high-density basalt rock wool core material with 0.4-0.6mm color-coated steel plates.

The assembly board can be disassembled and reinstalled in

different places, and the installation is simple and quick.

NUMERICAL CONTROL

STAMPING TECHNOLOGY

25mm aperture double row array,

0.4-0.6mm thick galvanized substrate

COMPOSITE

LAMINATING PROCESS

High density basalt

cotton core material

APPLICATION SCENARIO

Suitable for workshop, production workshop, laboratory, etc