SAMZOON Automotive Production Workshop Laboratory Soundproof Panel

Fa'atauga o oloa:

Effective width: 1150 mm/non-standard ≦ 1180 mm

Thickness of the product: 50mm/75mm/100mm/125mm/175mm/200mm (MAX 300mm)

length: according to user needs and the project request size production (generally) ≦ 8000 mm

Installation structure: male and female mouth splicing

Product description:

1.Soundproof board in the laboratory of the automobile production workshop

Utilizing precision CNC punching technology, a dual-row array of 25mm apertures is uniformly formed on the surface of the color-coated steel plate. Combined with a 0.4-0.6mm thick galvanized substrate, the strip-shaped perforations deliver exceptional noise reduction of 20-40 dB (meeting China's noise standards: daytime <000000>le;50 dB, nighttime <000000>le;40 dB). This configuration creates an optimized Helmholtz resonance structure. Tested by national acoustic laboratories, the Noise Reduction Coefficient (NRC) reaches 0.85 within the 500-4000Hz frequency range, effectively eliminating standing waves and reverberation.

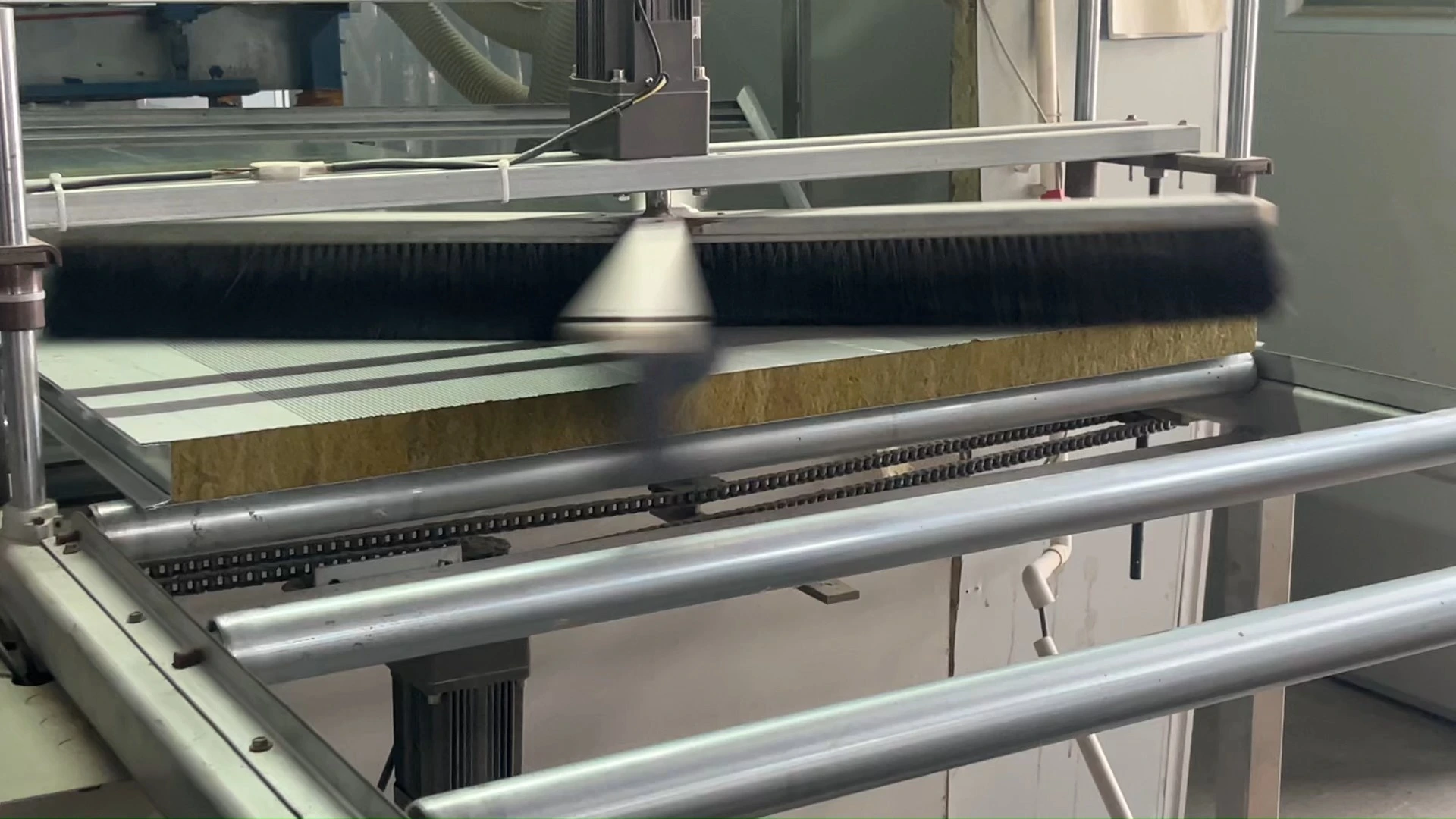

- Composite Lamination Process

A proprietary cold-bending lamination technique seamlessly integrates 100kg/m³ high-density basalt rock wool core material with 0.4-0.6mm color-coated steel plates. This innovation achieves a bending strength of 320MPa, overcoming the deformation issues common in traditional acoustic panels. The product meets Class A fire safety certification, ensures durability across all climates, and adheres to eco-friendly standards with zero pollution emissions.